Potable Water Pipes in Multi-Million Euro Superyacht Relined by CapCon

Customer: Yacht restoration crew in Marseille, France.

Site: This superyacht was built in Devonport, UK in 2008. The majestic €250million yacht is 270ft in length with a six-deck structure. It boasts a glass topped atrium, a winter garden style dining room, an indoor/outdoor spa with a retractable roof on the sun deck, helipad and other such amenities including her own car aboard. The yacht can accommodate 12 guests and 20 crew members.

Site: This superyacht was built in Devonport, UK in 2008. The majestic €250million yacht is 270ft in length with a six-deck structure. It boasts a glass topped atrium, a winter garden style dining room, an indoor/outdoor spa with a retractable roof on the sun deck, helipad and other such amenities including her own car aboard. The yacht can accommodate 12 guests and 20 crew members.

System: The potable water system running through the entire boat containing 60mm (2½”) and 75mm (3”) water pipes.

Problem: The yacht’s entire potable water system was suffering from serve internal corrosion due to electrolysis. This meant time and money were regularly spent flushing the system and replacing filters every few months.

Circumvention: Due to the entire potable water system being compromised to internal corrosion, a traditional pipe replacement would have required enormous amounts of refurbishment to the yacht. This would have resulted in six-decks of expensive furnishings being compromised and in many cases replaced, which would have been three times more expensive and taken numerous months to complete.

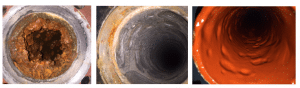

Solution: CapCon’s highly skilled technicians were able to solve this problem for the customer without causing any damage to the yacht. Firstly the team inspected the condition of the corroded pipes and assessed the nature of the problem. Borescope pictures revealed areas of the pipe with severe corrosion and significantly reduced diameters as a result.

Solution: CapCon’s highly skilled technicians were able to solve this problem for the customer without causing any damage to the yacht. Firstly the team inspected the condition of the corroded pipes and assessed the nature of the problem. Borescope pictures revealed areas of the pipe with severe corrosion and significantly reduced diameters as a result.

The CapCon team cleaned and restored the pipes back to their original state using a mild abrasive component which was shot-blasted through the entire system using air. A second inspection was conducted to ensure the pipe was smooth, clear, and ready for the liner to be installed.

CapCon’s unique ‘Nu Line’ liquid Epoxy was used to line the yachts entire potable water system. The liquid Epoxy was blown through the system to evenly coat the walls of the pipes, forming a smooth barrier between the pipe and water. This barrier coating was then cured before final inspection confirmed that the system was restored to the highest standard of quality.

The ‘CapCon’ technique was used to offer a permanent solution to the customer’s problem and prevent future corrosion from occurring. Our team of skilled experts were able to inspect, clean, and reline 110m of potable water pipelines throughout the yacht in less than ten days. Furthermore, no interior or exterior damage or destruction was caused to the superyacht during this time. CapCon’s unique Epoxy is UL certified safe to NSF/ANSI Standard 61 and has full WRAS approval, making it the only small-diameter relining solution suitable for potable water systems. The estimated life expectancy of the Epoxy is approximately 100 years and it has already withstood the test of time for more than 40 years in Japan and 25 years in the United States.

The ‘CapCon’ technique was used to offer a permanent solution to the customer’s problem and prevent future corrosion from occurring. Our team of skilled experts were able to inspect, clean, and reline 110m of potable water pipelines throughout the yacht in less than ten days. Furthermore, no interior or exterior damage or destruction was caused to the superyacht during this time. CapCon’s unique Epoxy is UL certified safe to NSF/ANSI Standard 61 and has full WRAS approval, making it the only small-diameter relining solution suitable for potable water systems. The estimated life expectancy of the Epoxy is approximately 100 years and it has already withstood the test of time for more than 40 years in Japan and 25 years in the United States.