Across modern industrial construction, drainage infrastructure is increasingly recognised as a critical interface between operational resilience and environmental responsibility. This becomes particularly evident in facilities operating around the clock, where system reliability must coincide with rigorous sustainability targets.

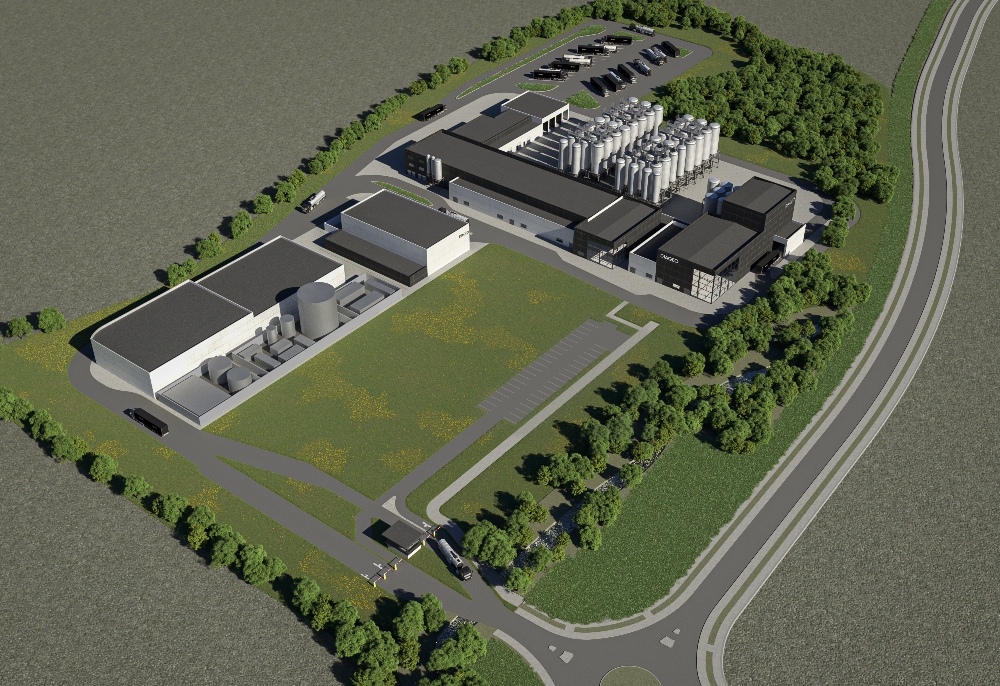

This was the challenge presented by Diageo’s new €200 million brewery in Kildare—the first carbon-neutral brewery in Ireland. Designed to operate 24/7, 365 days a year, and built across a 50-acre greenfield site, the project called for innovative engineering to ensure that rainwater management aligned with a site-wide zero-carbon strategy.

Capcon’s Role and Engineering Scope

Capcon was engaged for the full design, supply, and installation of a siphonic roof drainage system, inclusive of acoustic insulation to minimise operational disturbance across sensitive zones such as labs, control rooms, and workshops.

Key technical specifications

- 700+ metres of siphonic pipework

- 47 roof drainage outlets

- All connections are directed to pop-up points—an architectural requirement to maintain the flat roof profile

- Integration with structural and process services handled by Walls Construction

In parallel, the site was being prepared to host 92 silos, a renewable heating plant, and an on-site water recycling facility, which collectively support Diageo’s sustainability drive to eliminate up to 15,000 metric tonnes of carbon emissions annually.

Why Siphonic Drainage?

Unlike conventional gravity systems, which require graded pipework and often interfere with structural coordination, siphonic systems function under full-bore, vacuum-driven conditions. This enables high-capacity drainage with significantly smaller pipe diameters and fewer horizontal constraints.

Our decision to deploy siphonic technology was based on three key project demands

Operational Continuity: With brewing processes running without pause, the drainage system needed to maintain high reliability during extreme rainfall events without impeding access or requiring active pumping.

Spatial Efficiency: The brewery design prioritised space for production and process infrastructure. Siphonic routing reduced the footprint and allowed us to run drainage pipework around process vessels and structural steel without rework or compromise.

Carbon Reduction: By eliminating the need for pitched pipe runs, oversized bore diameters, and pump assistance, the siphonic system reduced both material quantities and embodied carbon. Compared to traditional approaches, the system cut material use and labour time and contributed directly to Diageo’s carbon-neutral commitment.

Acoustic Considerations

To support Diageo’s quality and safety standards, Capcon added acoustic insulation across the siphonic network. This was critical in zones adjacent to control systems and laboratory environments, where structure-borne noise during rainfall could disrupt operations or interfere with sensitive equipment.

Integration with Broader Sustainability Goals

Walls Construction’s remit spanned civil, structural, architectural, and M&E works, including process integration with brewing vessels and tanks. Seamless coordination across these disciplines was essential, particularly given the brewery’s reliance on 100% renewable energy and advanced process technologies to minimise water and energy use.

Capcon’s system was engineered to interface cleanly with the building’s envelope and services, while conforming to sustainability-driven architectural standards, such as concealed drainage points and a flat roof configuration optimised for water runoff recovery.

Conclusion: A Precedent for Sustainable Drainage in Industrial Construction

This project exemplifies how rainwater systems can be repositioned as strategic enablers of both operational resilience and environmental compliance. By applying siphonic principles and aligning closely with project stakeholders from the design stage onwards, we delivered a solution that is technically robust, materially efficient, and fully integrated into the wider sustainability framework of the facility.

As future industrial developments increasingly aim for net-zero outcomes, early engagement with specialist drainage engineers will be fundamental in ensuring that critical infrastructure systems do not just follow the environmental agenda.

Image source:

Think Business – https://www.thinkbusiness.ie/articles/diageo-brewery-kildare-construction-jobs-carbon-neutral/