Picture this: you’re standing on a massive airport terminal roof during a torrential downpour. Traditional rainwater drainage would need dozens of downpipes, each one compromising your architectural vision and eating into valuable interior space. But there’s a better way.

Siphonic drainage flips conventional thinking on its head. Instead of letting water trickle down partially filled pipes by gravity alone, these systems create a powerful vacuum effect – think of it as turbocharging your roof drainage. The pipes run completely full, generating a siphonic action that whisks water away at velocities that would make traditional systems jealous.

Here’s where it gets interesting for engineers like you. The technology leverages precise hydraulic principles and engineered components to achieve flow rates multiples higher than conventional gravity systems. Anti-vortex plates at each outlet prevent air from entering the system, maintaining that crucial negative pressure that makes the whole thing work.

Principles of Siphonic Drainage

Basic Concepts and Functionality

Let me break down how this works. At its heart, a siphonic system is deceptively simple – yet the engineering behind it is anything but.

The magic happens at the roof outlet. Each siphonic drain incorporates a baffle plate (sometimes called an anti-vortex plate) that prevents air from being sucked into the system. No air means no vortex formation – you know, that swirling funnel you see when your bathtub drains. Without air in the pipes, water fills them completely, creating negative pressure that literally pulls rainwater off your roof.

What does this mean for your designs? Smaller pipe diameters for starters. We’re talking 75mm pipes doing the work of 160mm conventional ones. The water rockets through at high velocity – up to 6 metres per second, significantly faster than in gravity systems. And here’s the kicker: you can run these pipes horizontally, at zero falls. No gradients needed until you’re ready to drop down at a convenient location.

Comparison with Gravity Drainage Systems

Traditional gravity drainage? It’s been around forever, and there’s comfort in that familiarity. But let’s be honest about its limitations.

Gravity systems need slope – typically 1:100 minimum – which means deeper ceiling voids, coordination headaches with other services, and structural implications. They require larger diameter pipes because they only run one-third full at best. More pipes, more penetrations, more potential leak points.

Siphonic systems laugh at these constraints. With negative pressure doing the heavy lifting, you can route pipes completely level. Fewer downpipes mean cleaner architectural lines – music to any architect’s ears. The Changi project mentioned earlier – their engineers specified siphonic drainage because conventional systems would have been “virtually impossible” given the building’s innovative design.

Design and Components

Design Considerations

Here’s where the rubber meets the road – or rather, where the rain meets the roof.

Designing a siphonic system isn’t something you sketch on the back of a napkin. It demands hydraulic modeling software that can simulate your specific rainfall scenarios – something our specialist team at Capcon consistently delivers with precision. You’re calculating for that 1-in-100-year storm event (plus climate change factors, because who’s not these days?).

Your design inputs? Roof area, rainfall intensity based on local meteorological data, outlet positions, and desired discharge points. The software crunches these numbers to determine pipe sizes, flow velocities, and pressure profiles throughout the system. The expertise of Capcon’s experienced engineers come to the fore here to ensure every building is designed to exceed the client’s expectations, offering maximum protection to building.

Material selection matters too. HDPE has become the go-to for many projects – it’s smooth, corrosion-resistant, and handles the pressure differentials like a champ. Some high-end projects opt for stainless steel, especially where longevity is paramount.

Key Components of Siphonic Systems

Let’s talk about hardware. Every component in a siphonic system has a job, and they’d better do it well:

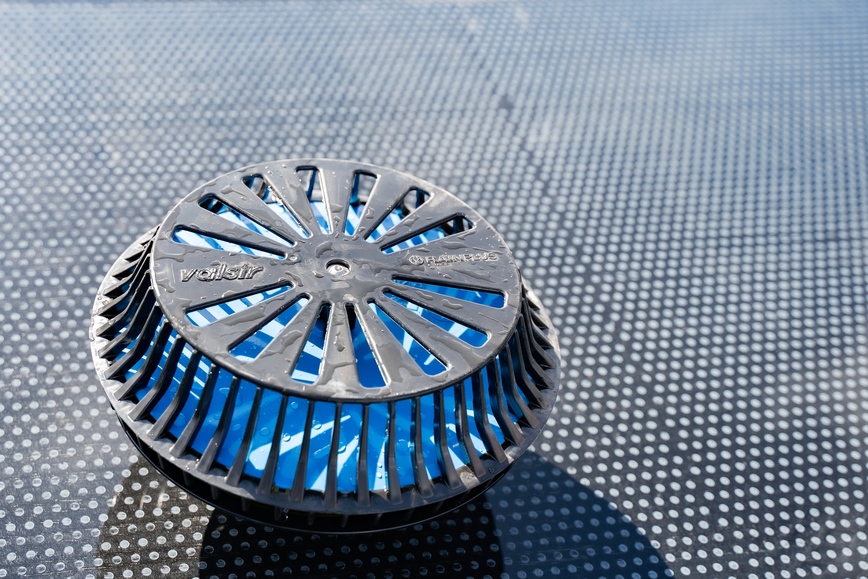

The Roof Outlet – Siphonic outlets feature sophisticated anti-vortex designs that have evolved significantly. The latest generation includes self-cleaning profiles and integrated debris screens. Some even incorporate heating elements for those tricky cold-climate installations.

The Baffle Plate – The unsung hero. This precisely engineered component sits in the outlet, preventing air entrainment. Without it, you’ve just got a gravity system.

Pipework – Smaller diameter than traditional, yes, but don’t let that fool you. These pipes see serious action and far outperform their gravity counterparts. Full-bore flow creates significant forces, so proper support and expansion joints are non-negotiable.

The Collector Pipe – Where individual runs converge. Sizing here is critical – too small and you’ll create bottlenecks, too large and you’ll lose velocity.

Installation and Implementation

Installation Process

Installing siphonic drainage is where theory meets reality, and precision is everything.

First comes the roof survey. Every undulation, every potential ponding area needs mapping. Your designer should be checking structural capacities too – full-bore flow means heavier pipes.

The installation sequence matters:

- Outlet positioning – Get this wrong and no amount of clever pipework will save you

- Pipe routing – Taking advantage of that horizontal capability while planning for thermal movement

- Support systems – These pipes will shake when running full bore

- System priming – That first controlled flood to ensure everything works as designed

On large projects, as we’ve seen at Capcon, even a small sealing issue at just one outlet can prevent an entire system from priming. This is the precision level we’re talking to.

Contractors and Services

Siphonic drainage solutions demand a high level of skill and expertise – and every engineer at Capcon is trained to meet those requirements. It’s not a solution just anyone can install and that’s the reality of working with advanced systems like these.

You need contractors who understand hydraulic principles, not just pipe fitting. Look for Siphonic Roof Drainage Association members, or firms with proven track records on similar projects. At Capcon, we have made and built our reputation on getting these systems right.

What should you expect from a specialist contractor? Design verification for starters – they should check and challenge the hydraulic calculations. Installation supervision is crucial. And they should provide comprehensive commissioning, including flow testing under various scenarios.

Advantages and Considerations

Efficiency and Performance Benefits

Here’s why siphonic systems are winning converts across the industry:

Raw Performance – We’re talking about flow rates that can handle extreme rainfall intensities on massive roofs. The new airport terminal in Poland? Siphonic drainage was the only viable option for those enormous roof areas.

Design Freedom – Architects love the reduced visual impact. Structural engineers appreciate fewer penetrations. MEP coordinators enjoy the routing flexibility. Everyone wins.

Space Efficiency – In a recent data centre project, switching from gravity to siphonic drainage freed up 300mm of ceiling void height. That’s the difference between fitting in all your services comfortably or having a coordination nightmare.

Operational and Economic Impacts

The financial aspect– because that’s what gets projects approved.

Initial Costs – Yes, siphonic outlets cost more than traditional drains. But you need fewer of them. Smaller pipes and less pipework, less excavation for underground drainage. On large projects, total installed cost typically comes out 20-40% lower than conventional systems.

Lifecycle Benefits – Self-cleansing action means less maintenance. No slope means no low points where debris accumulates. Facility manager’s report 50% reduction in drainage maintenance calls compared to traditional systems.

Risk Mitigation – Faster drainage means reduced risk of roof collapse due to ponding. For mission-critical facilities, that’s not just about money – it’s about business continuity.

Case Studies and Applications

Notable Implementations Globally

Real projects, real results:

Diageo’s Brewery, Co. Kildare, Ireland – Pinned as Ireland’s first carbon neutral brewery, Capcon was engaged for the full design, supply and installation of a siphonic roof drainage systems inclusive of 700+ metres of pipework and 47 roof drainage outlets. All connections were directed to pop-up points – an architectural requirement to maintain the flat roof profile.

Project Oriel, Kent, United Kingdom – A state-of-the-art hospital development located in the heart of London. This ambitious project presented many logistical complexities, such as access for deliveries and constrained working areas, necessitating a highly coordinated approach to design, planning, and execution. Working closely with Bouygues we ensure our design integrated seamlessly within the intricate framework of this high-profile healthcare facility.

Data Centre, Johor, Malaysia – This mission critical facility required Capcon’s expertise in design and installation of an external siphonic drainage system that ensured rapid rainwater removal and provided superior protection against extreme rainfalls events. Rainwater drainage systems in Malaysia adhere to regulatory standards based on the British Standards BS 12056-3:2000 and BS 8490:2007 and the siphonic drainage system designed for this Johor data centre naturally complies with these standards. It’s worth noting, the rainfall intensity in Malaysia is more than double that of most UK and EU locations, so local rainfall levels are always considered in the design of any rainwater drainage system.

Ready to explore siphonic drainage for your project? Contact Capcon Engineering for project-specific siphonic system evaluation or CPD-accredited seminars for your design team. Let’s discuss how modern drainage solutions can benefit your next project.